Outdoor led display light box street light billboard

Outdoor LED display installation and maintenance methods

Let's also share the maintenance and reinforcement methods of outdoor LED billboards:

1. Foundation expansion method: By setting up a concrete enclosure or a reinforced concrete enclosure, the area of the bottom foundation of the outdoor LED billboard is increased, and the uneven settlement of the foundation caused by the small bottom area and insufficient bearing capacity of the billboard foundation is changed.

2. Pit underpinning method: Concrete is poured directly after digging a pit under the underpinned foundation.

3. Pile underpinning method: a method of reinforcing the foundation by setting up various types of piles such as static pressure columns, driven piles, and cast-in-place piles at the lower part or both sides of the billboard foundation.

4. Grouting underpinning method: The chemical slurry is injected into the foundation evenly, and the original loose soil or cracks are cemented and solidified through the slurry, so as to improve the bearing capacity of the foundation and achieve the effect of waterproof and impermeability.

Deflection correction is to use artificial means to make the tilted foundation reverse tilt operation, so as to achieve the purpose of correcting the tilt of outdoor LED billboards. There are two commonly used methods for rectifying the foundation of outdoor billboards:

1. Forced landing correction method: take measures to prevent the subsidence on one side of the outdoor LED billboard foundation with more settlement, and take forced landing measures on the other side. The forced landing methods include: loading steel ingots or stones, building cantilever beams, digging soil for forced landing, and water injection for deviation correction.

2. Lifting rectification method: In the part where the foundation of the inclined billboard has a large settlement, adjust the lifting amount of each part of the billboard to make it rotate along a certain point or a certain straight line to achieve the purpose of restoring the original position.

As a typical representative of outdoor LED display applications, outdoor LED billboards are suitable for many fields because of their easy maintenance, energy saving, stable and reliable operation. Basically, there are many forms of common LED displays, but no matter which one, good color expression is a beautiful scenery in a bustling city.

In order to use outdoor billboards well, installation and debugging are essential. For technical construction personnel, knowing the skills of outdoor construction and maintenance of advertising screens will effectively promote the promotion of business advertising and information dissemination, and it is also necessary for technical construction personnel to be familiar with Specifically, there are four steps in the installation of outdoor billboard LED electronic displays: site investigation, equipment construction, installation, and commissioning.

First of all, we have to conduct a field survey according to the actual situation. Specifically, before the outdoor LED display is installed, it should be tested according to the specific environment, topography, luminous radiation range, brightness acceptability and other parameters. The commander implements a unified hoisting plan to ensure that the equipment can be used normally and stably. Different situations are treated differently, so as to adopt a more appropriate method.

Secondly, after the specific plan is determined according to the results of the on-site investigation, we will carry out the construction of LED equipment. For the construction of some outdoor LED billboards, we must distinguish between wall advertising screens, hanging advertising screens and roof advertising screens. In actual installation, cranes and hoists should be used for segmented hoisting according to the distance and height, and at the same time, the above personnel should cooperate with each other. There is a better installation and use process for the LED advertising screen for high-altitude operation. During the construction process, safety and refined operation are the first requirements.

Once again, after the construction is completed, in order to achieve the best transmission effect, we also need to debug the luminous radiation range. Due to the different radiation ranges, the viewing angles of the LED display screens are also different. The fixed installation work of the outdoor LED display screens should be carried out according to the field acceptance ability and your usual viewing angle range, so as to ensure that from every angle, you can see the normal brightness and brightness. Balanced images, subtitle information, large viewing angle and appropriate brightness can maximize benefits.

Finally, in order to deliver it smoothly, we need to carry out follow-up inspection and maintenance. Subsequent testing includes many areas, such as LED display waterproofing, heat dissipation layer, LED display waterproof coating, rain shielding area on the display screen, heat dissipation space on both sides, power supply line, etc. These basic components constitute the entire stability. Good graphic led display. Of course, later technical maintenance is also very important. We need to carry out unified management and maintenance for these parts. When the product is rusted, unstable or damaged, it needs to be replaced in time to ensure the safe use of the entire display.

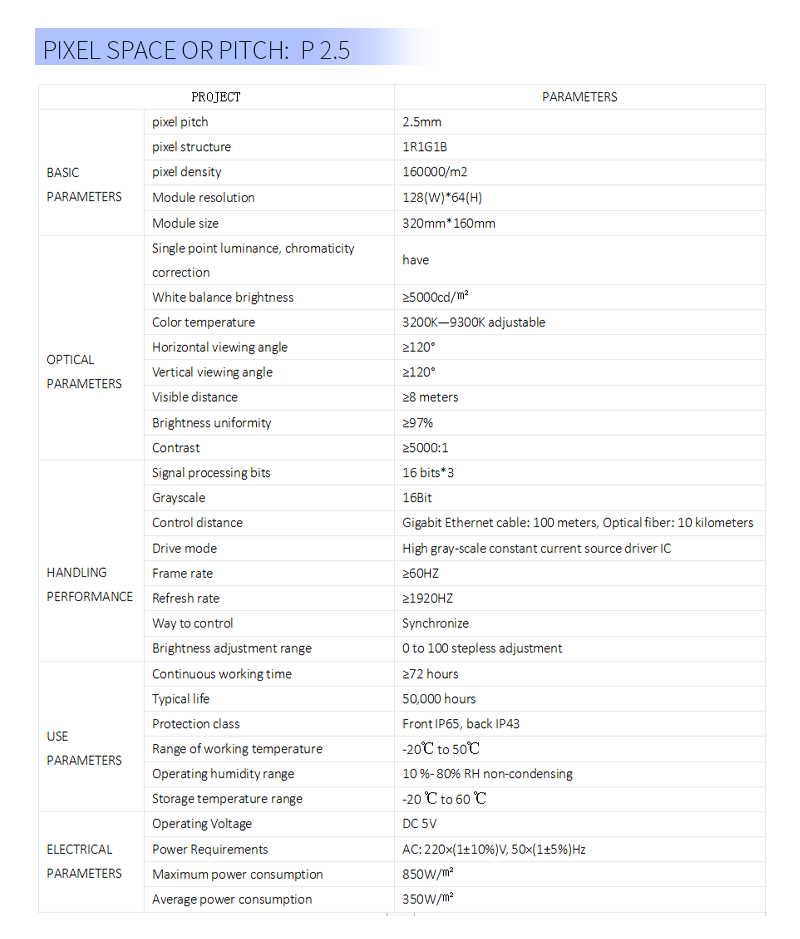

|

project |

parameter |

Remark |

|

|

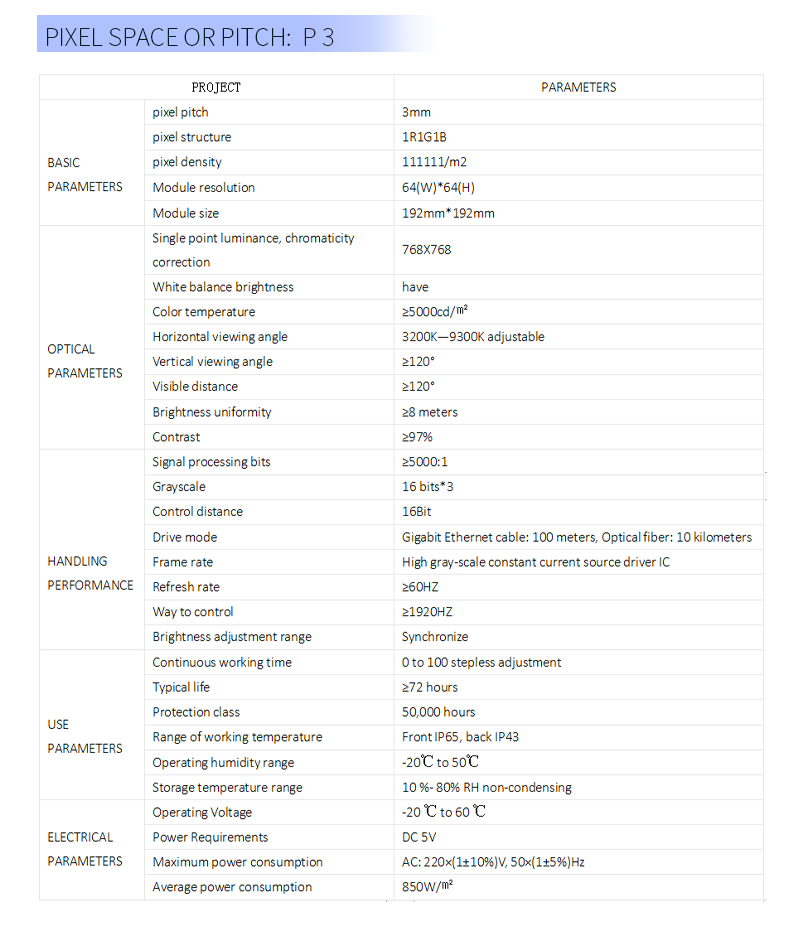

BASIC PARAMETER |

pixel pitch | 2.5mm _ |

|

| pixel structure | 1R1G1B |

|

|

| pixel density | 160000 /m 2 |

|

|

| Module resolution | 128 (W)* 64 (H) |

|

|

| Module size | 320mm * 160mm _ |

|

|

|

OPTIC PARAMETER |

Single point luminance, chromaticity correction | have |

|

| white balance brightness | ≥ 5 0 00cd/㎡ |

|

|

| color temperature | 3200K—9300K adjustable |

|

|

| Horizontal viewing angle | ≥ 120° |

|

|

| vertical viewing angle | ≥ 120° |

|

|

| Visible distance | ≥8 meters |

|

|

| Brightness uniformity | ≥97% |

|

|

| Contrast | ≥ 5 000:1 |

|

|

|

PROCCESSING PARAMETER |

Signal processing bits | 16 bits*3 |

|

| grayscale | 16Bit |

|

|

| control distance | Gigabit Ethernet cable: 100 meters, Optical fiber: 10 kilometers |

|

|

| drive mode | High gray-scale constant current source driver IC |

|

|

| frame rate | ≥ 60HZ |

|

|

| refresh rate | ≥ 1920 Hz |

|

|

| way to control | Synchronize |

|

|

| Brightness adjustment range | 0 to 100 stepless adjustment |

|

|

|

OPERATION PARAMETER |

Continuous working time | ≥72 hours |

|

| Typical life | 50,000 hours |

|

|

| Protection class | Front IP65, back IP43 |

|

|

| range of working temperature | -20℃ to 50℃ |

|

|

| Operating humidity range | 10 %- 80% RH non-condensing |

|

|

| Storage temperature range | -20 ℃ to 60 ℃ |

|

|

|

ELECTRIC PARAMETER |

Operating Voltage | DC 5V |

|

| Power Requirements | AC: 220×(1±10%)V, 50×(1±5%)Hz |

|

|

| Maximum power consumption | 8 5 0W/ ㎡ |

|

|

| Average power consumption | 350W/ ㎡ |

|

|