Car LED Transparent Screen p2.6-5.2mm

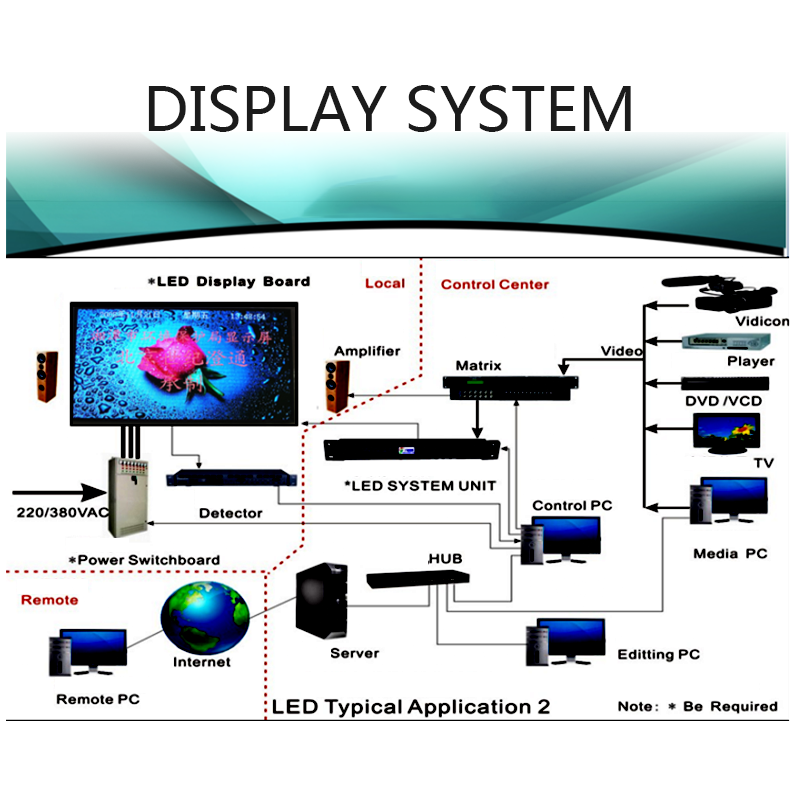

How to repair the LED display panel and how to troubleshoot the fault of the unit board

The composition of the full-color LED display is composed of the most basic LED unit board. If there is a problem with the unit board, it will directly affect the display effect of the entire LED screen, such as the common color difference area or black screen and other phenomena! At this time, how to detect and distinguish whether the LED display unit board is good or bad becomes very important, and it has also become a concern of many LED display manufacturers. method:

Full color LED display

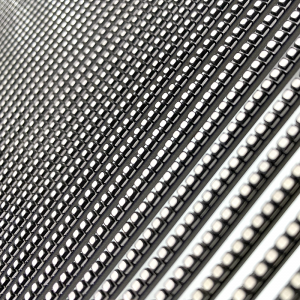

1. LED unit board sheet

In fact, many LED unit board manufacturers are now using cheap flame retardant cardboard or single-sided fiberboard as the PCB circuit board for LED lights in order to compete for customers at low prices. There is not much difference when people who don't know use it. It is easy to break due to moisture, ultraviolet damage, oxidation, etc. after using it for about half a year, which will easily lead to the scrapping of the entire LED unit board. A good LED display unit board uses a double-sided full glass fiber PCB board, although the cost will be relatively high, but it will be more secure.

2. IC devices

Whether the brands of IC devices are consistent. Or what model and how many ICs are used will also greatly affect the quality of the LED unit board. In order to save costs, some LED display manufacturers often deliberately reduce the number of ICs when producing unit boards, and also include other brands of ICs.

3. LED lamp beads and chips

The naked eye cannot distinguish the quality of the lamp beads, it can only be distinguished by long-term testing. Generally, for informal LED display manufacturers, the products will be powered on before leaving the factory to check whether the LED display can operate normally, but it will not undergo a long-term aging test. After all, a long-term aging test will affect the cost and labor cost. As a Shenzhen LED display brand manufacturer, Lihelilai has a strict production and quality inspection process. Before the products are shipped, the lighting and aging test is carried out for at least 96 hours to ensure that each product can be delivered to customers in good condition.

4. Welding quality

Check whether the patch has components missing or wrongly pasting, and whether there is a short circuit of component pin burrs. Check whether the solder joints of the straight plug-in are smooth and round, whether the board surface is clean and tidy, and there is no false soldering or missing soldering. Check the flatness of the light-emitting dot matrix and the consistency of the ink color.

|

project |

parameter |

Remark |

|

|

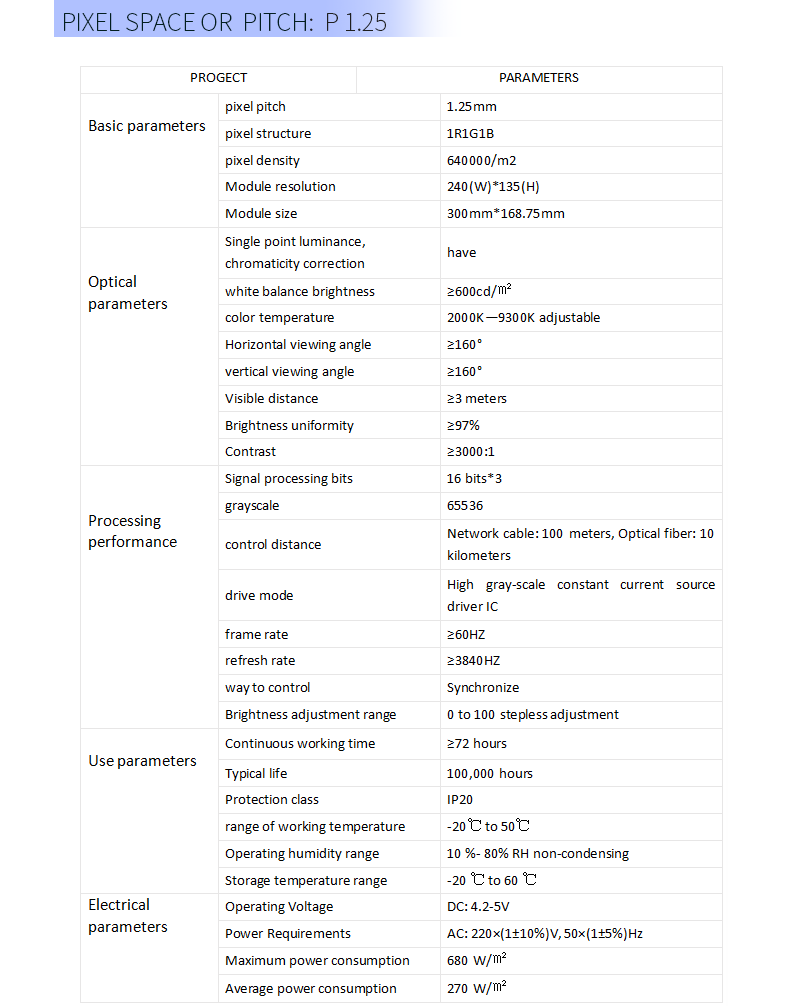

BASIC PARAMETER |

pixel pitch | 1.25mm _ | |

| pixel structure | 1R1G1B | ||

| pixel density | 640000 /m 2 | ||

| Module resolution | 240 (W)* 135 (H) | ||

| Module size | 300mm * 168.75mm | ||

| Box size | 1200*675mm | ||

| Box weight(Kg) | 19.5kg | ||

|

OPTIC PARAMETER |

Single point luminance, chromaticity correction | have | |

| white balance brightness | ≥600 cd/㎡ | ||

| color temperature | 20 00K—9300K adjustable | ||

| Horizontal viewing angle | ≥ 160° | ||

| vertical viewing angle | ≥ 1 6 0° | ||

| Visible distance | ≥3 meters | ||

| Brightness uniformity | ≥97% | ||

| Contrast | ≥3000:1 | ||

|

PROCCESSING PARAMETER |

Signal processing bits | 16 bits*3 | |

| grayscale | 65536 | ||

| control distance | Network cable: 100 meters, Optical fiber: 10 kilometers | ||

| drive mode | High gray-scale constant current source driver IC | ||

| frame rate | ≥ 60HZ | ||

| refresh rate | ≥ 384 0 Hz | ||

| way to control | Synchronize | ||

| Brightness adjustment range | 0 to 100 stepless adjustment | ||

| Operation

parameter |

Continuous working time | ≥72 hours | |

| Typical life | 100,000 hours | ||

| Protection class | IP20 | ||

| range of working temperature | -20℃ to 50℃ | ||

| Operating humidity range | 10 %- 80% RH non-condensing | ||

| Storage temperature range | -20 ℃ to 60 ℃ | ||

| Electric

parameter |

Operating Voltage | DC: 4.2-5V | |

| Power Requirements | AC: 220×(1±10%)V, 50×(1±5%)Hz | ||

| Maximum power consumption | 680W / ㎡ _ | ||

| Average power consumption | 270W / ㎡ _ | ||