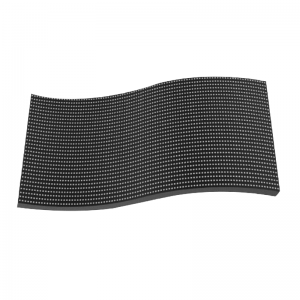

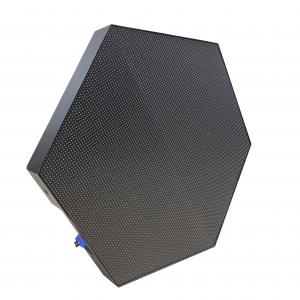

indoor curved led video wall panel soft led module

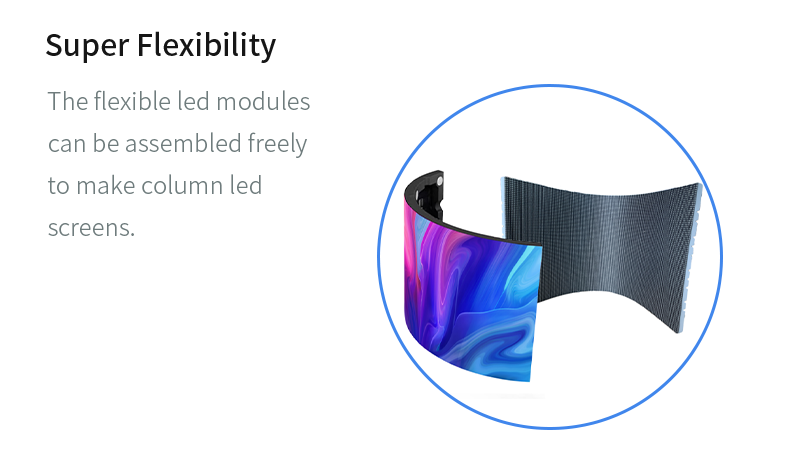

Features of LED display soft module:

1. Using special materials and advanced technology, ultra-thin and ultra-light, the thickness of the three sizes of modules is 9-10mm,

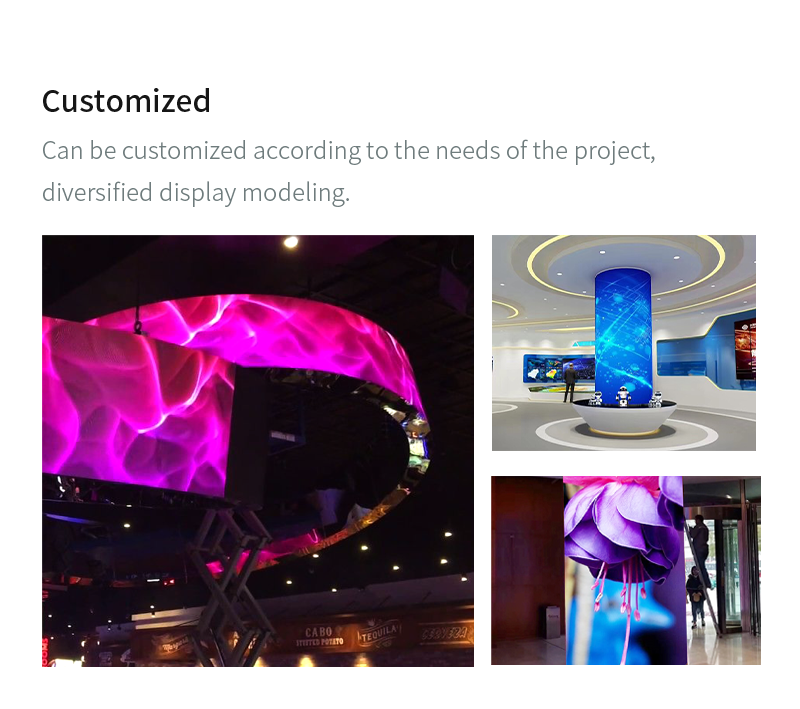

Strong flexibility, can be bent up to 120°, and can be shaped into any shape (cylinder, wave, ring, spherical, heterosexual, etc.)

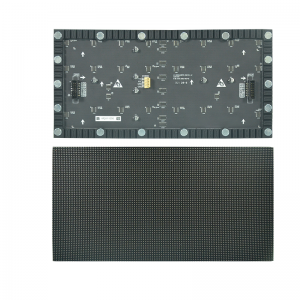

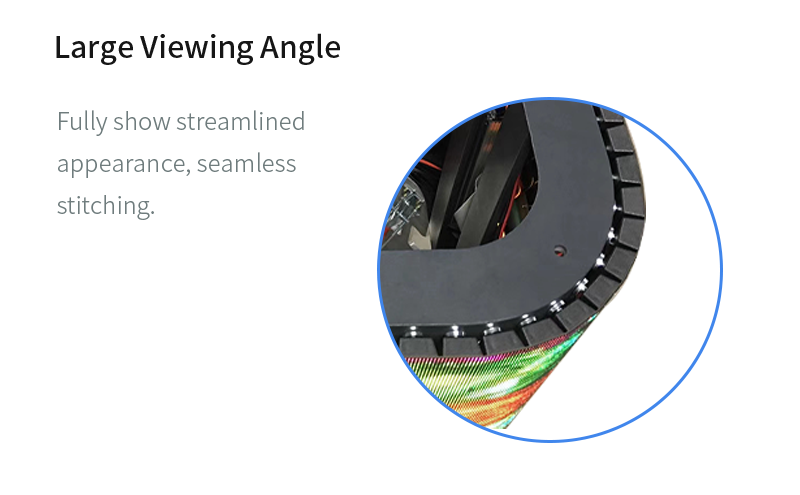

2. Adopt strong magnetic adsorption installation, direct adsorption, more convenient installation and maintenance. The box body is omitted, the structural load is reduced, and the cost is effectively reduced. Support floor-standing, hanging, embedded, hoisting and other installation methods

3. Using a magnetic suction module, the left and right and up and down directions can be adjusted by the translation of the module; by rotating the magnetic column, the height can be adjusted, thereby adjusting the flatness of the entire screen body

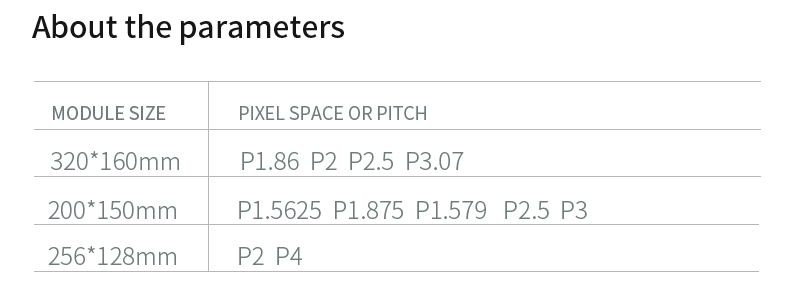

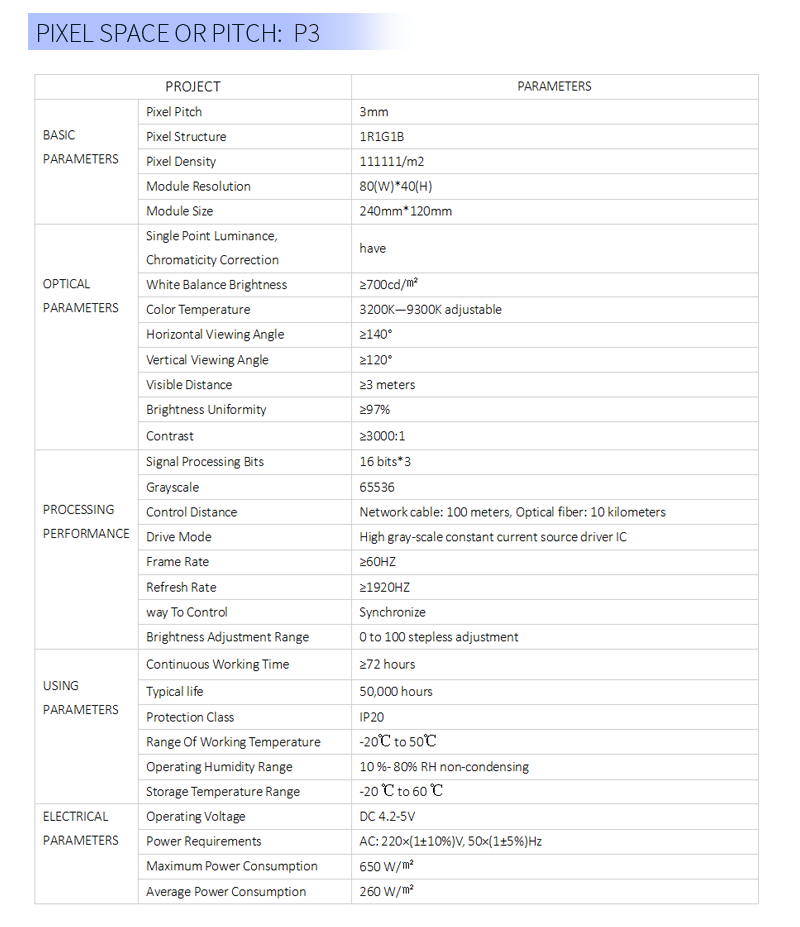

Module size: 320*160mm 256*128mm 240*120mm 200*150mm

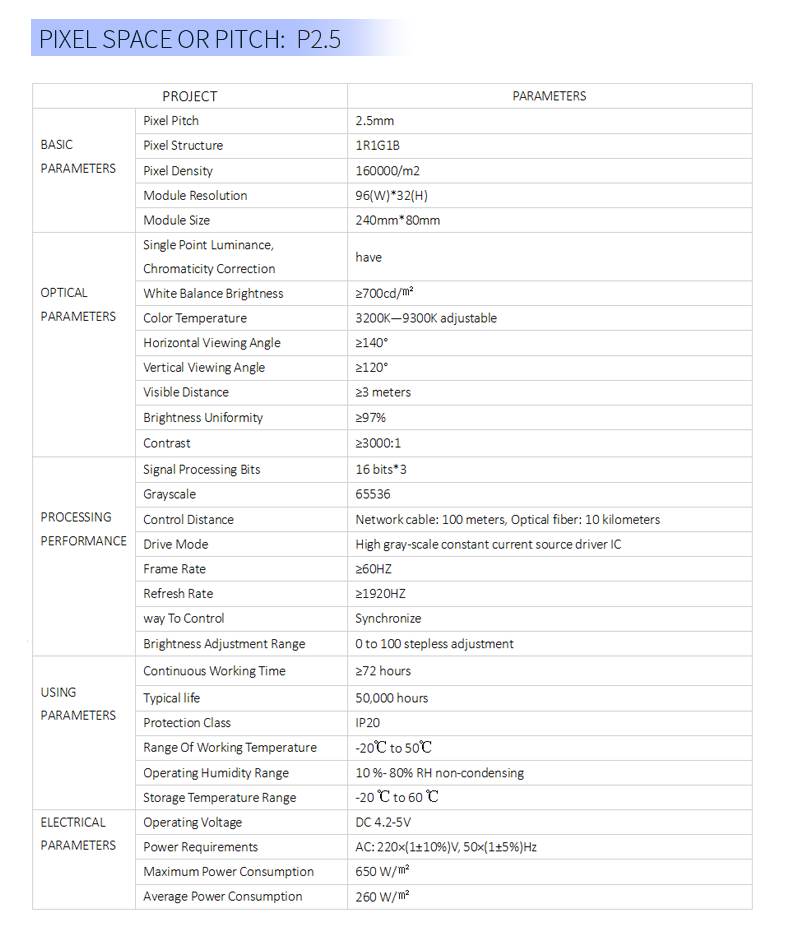

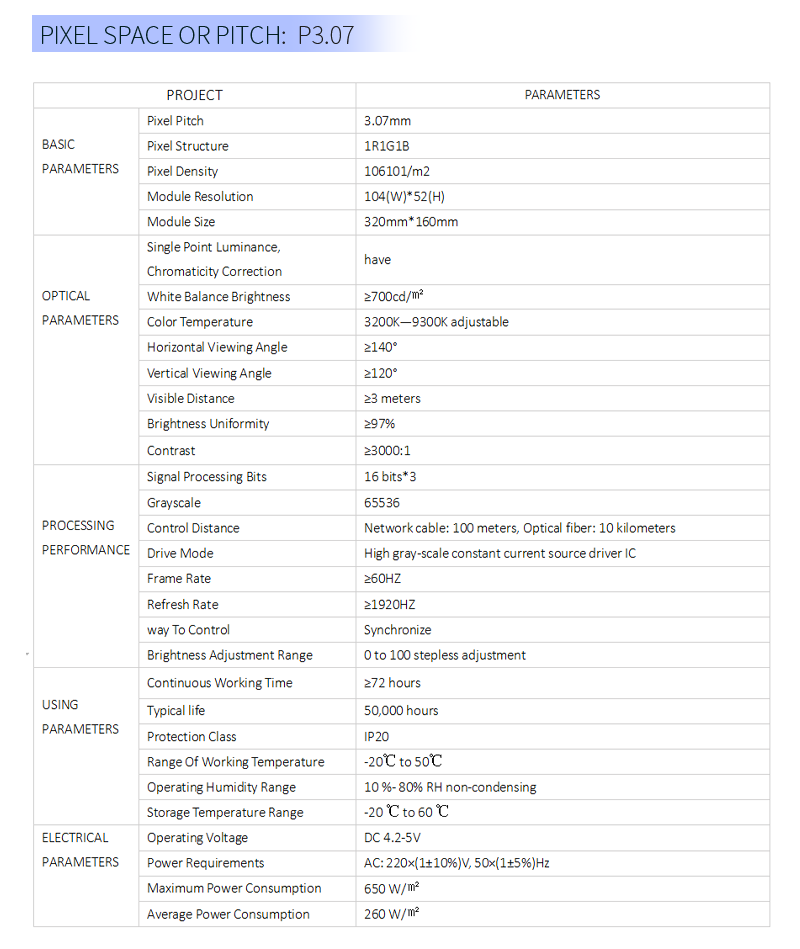

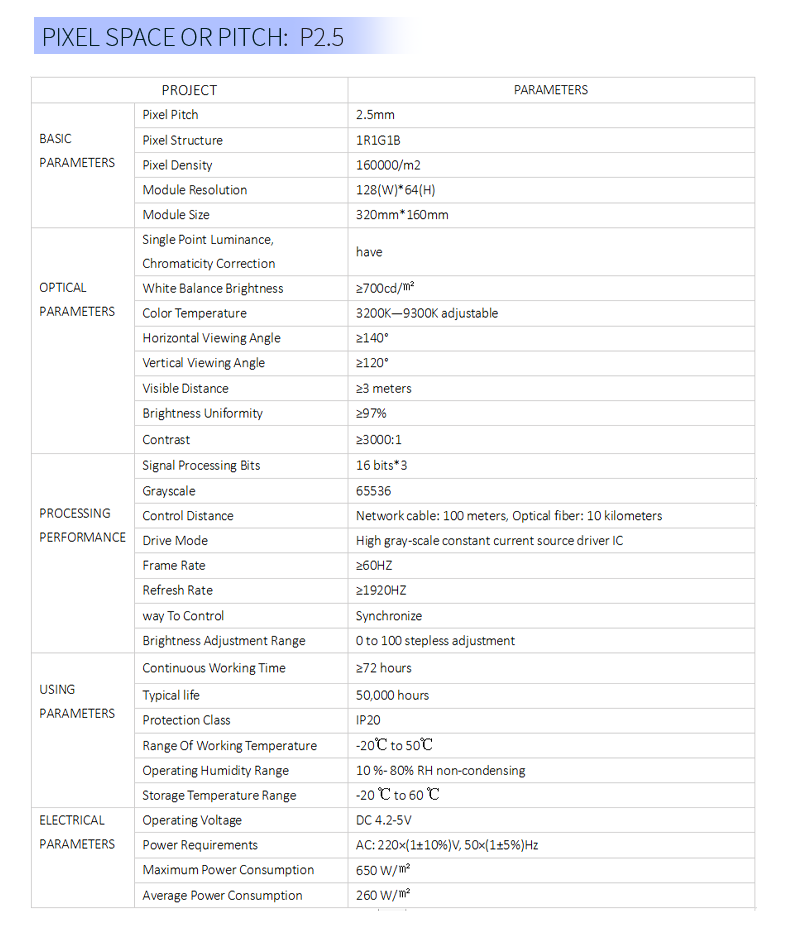

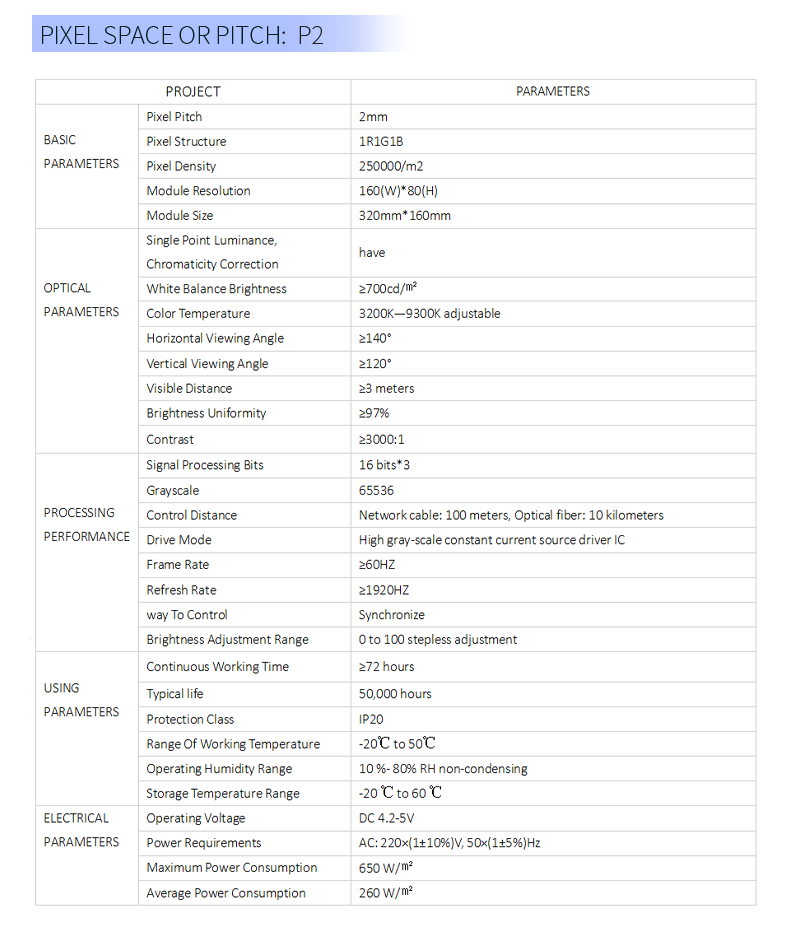

Module size: 320*160mm:

PITCH: P1.86mm P2mm P2.5mm P3.07mm

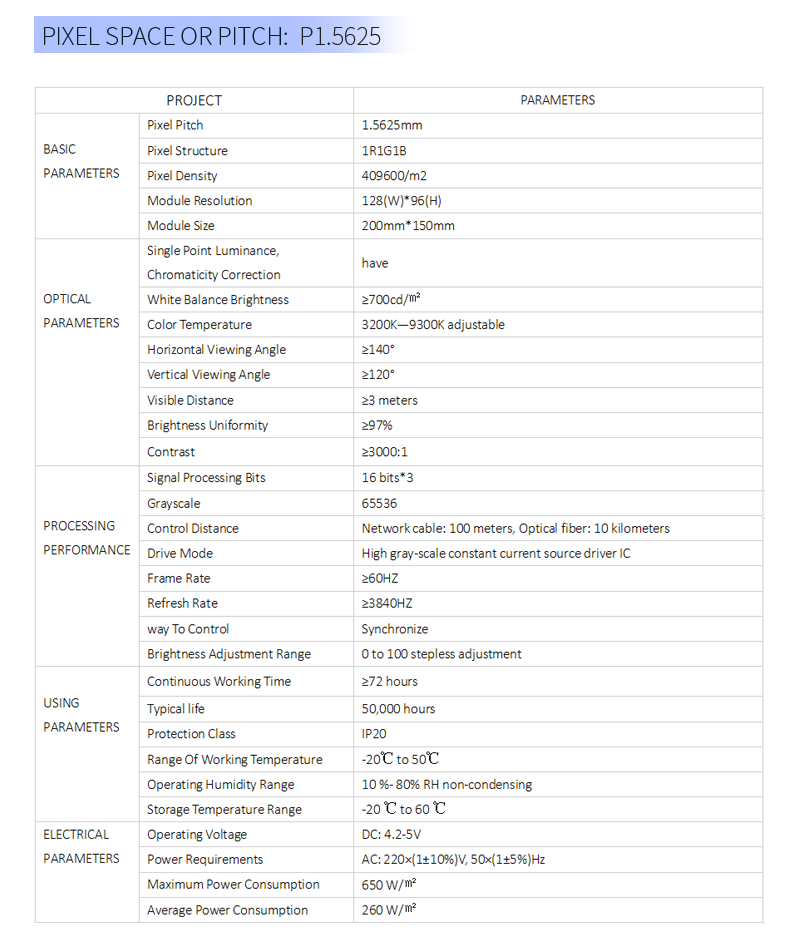

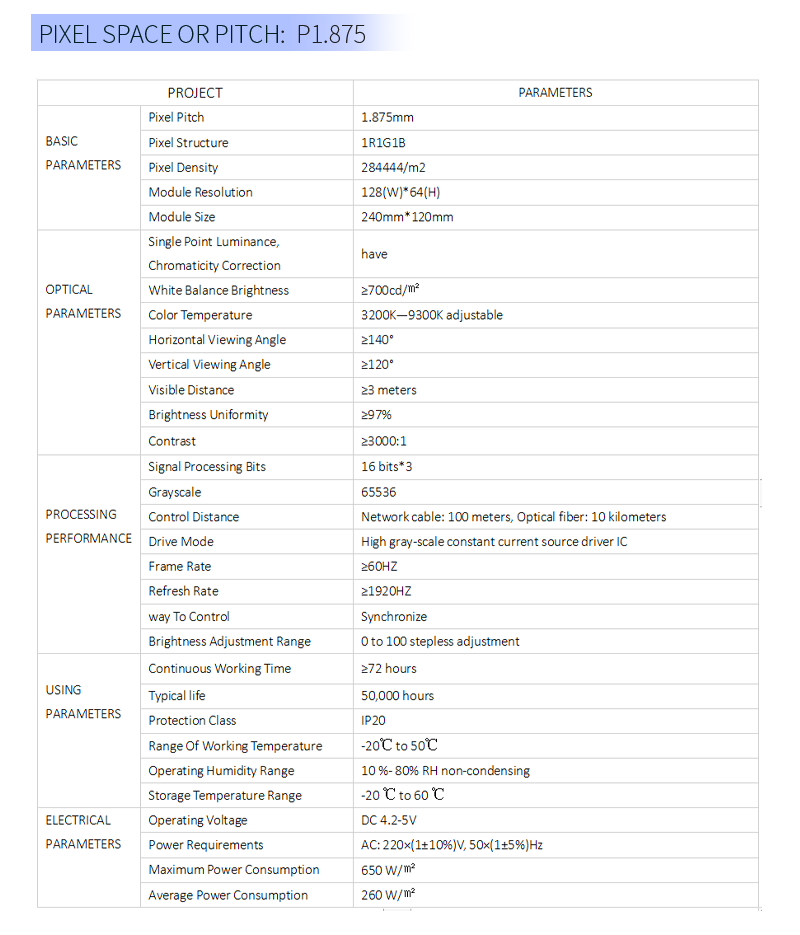

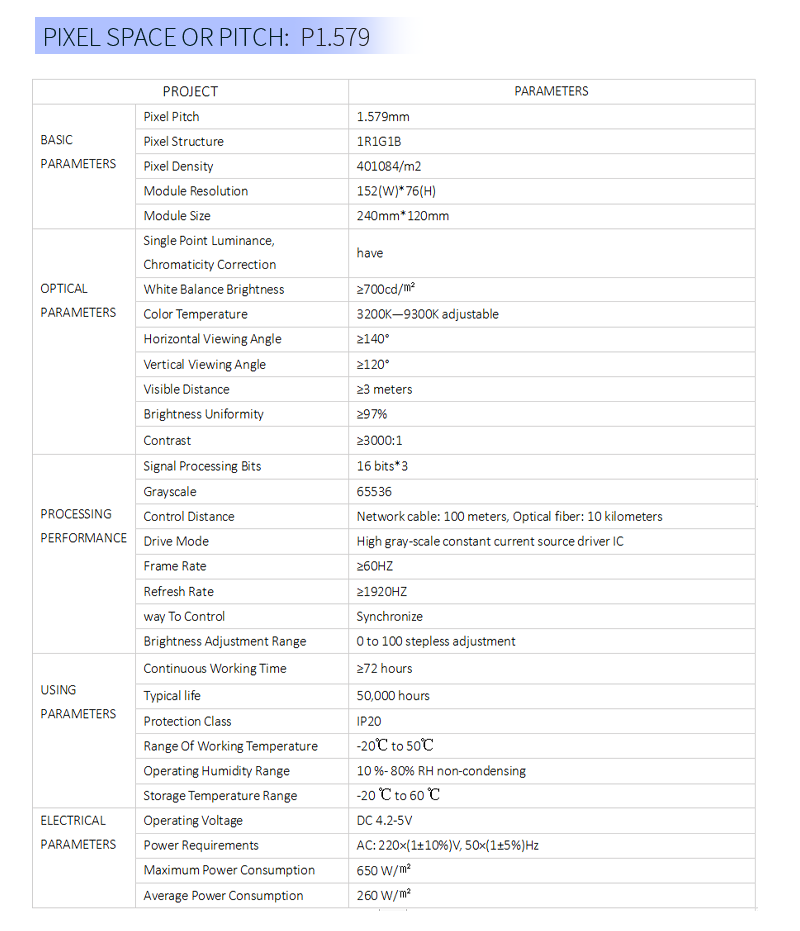

Module size: 200*150 mm:

PITCH: P1.5625mm P1.875mm P1.579mm P2.5mm P3mm

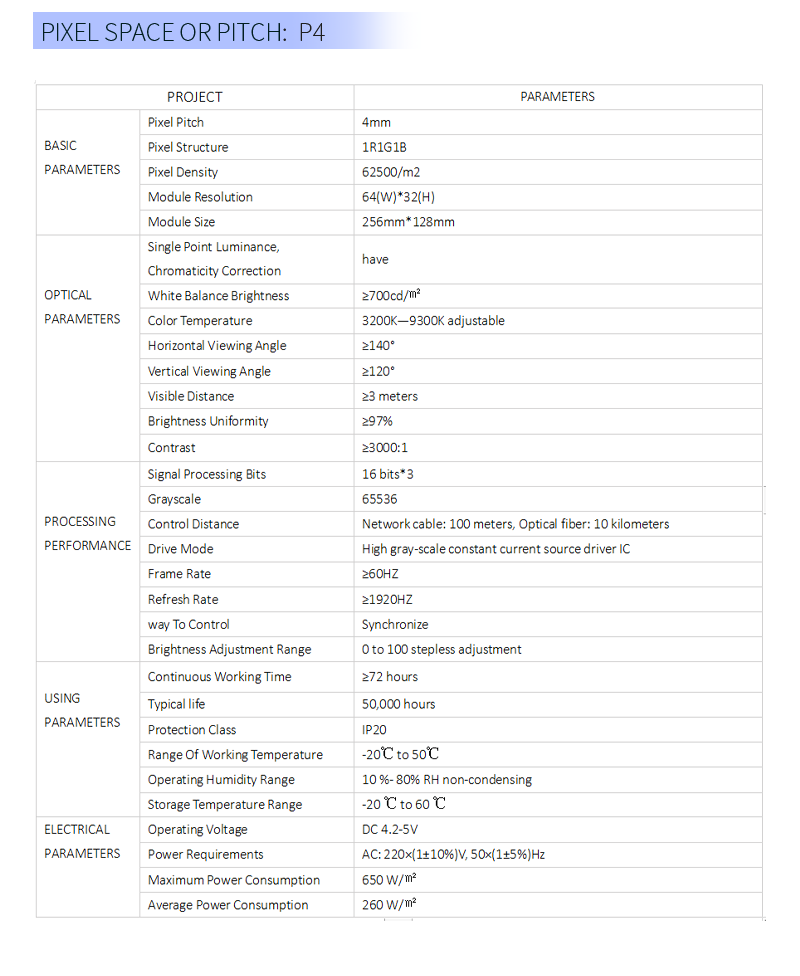

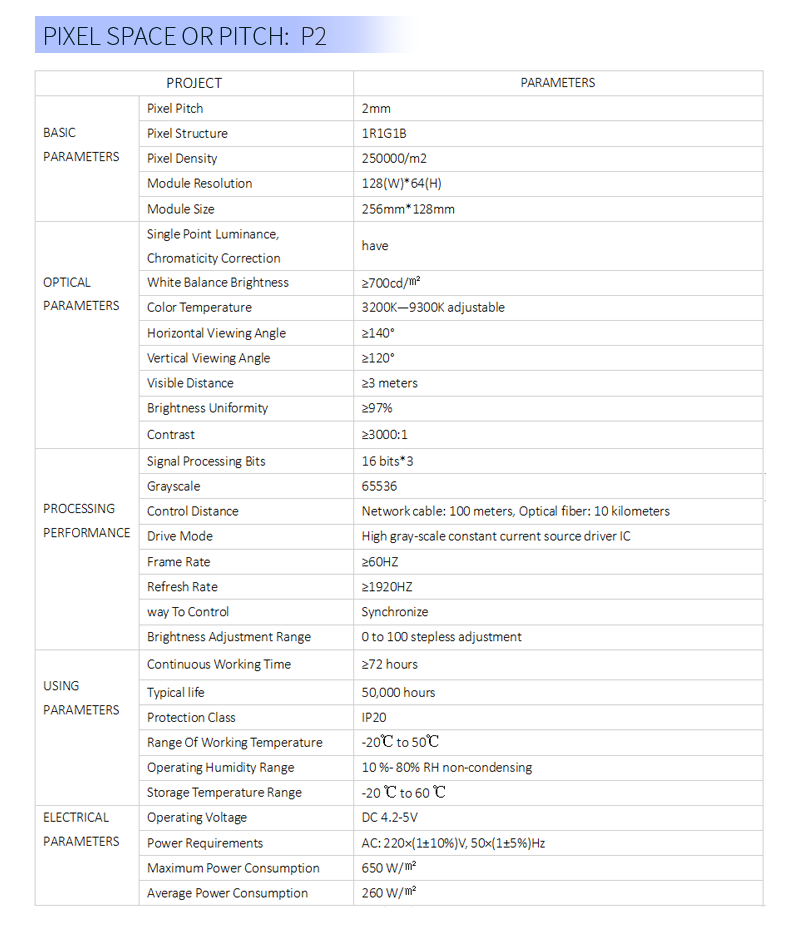

Module size: 256*128mm:

PITCH: P2mm P4mm

|

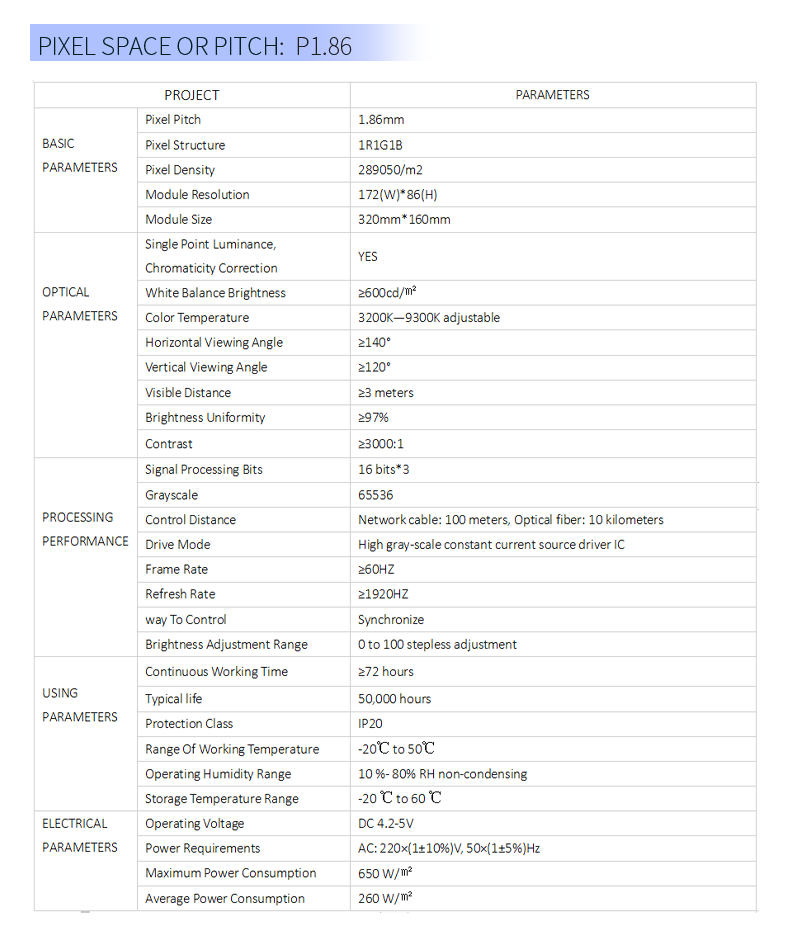

project |

parameter |

Remark |

|

|

BASIC PARAMETER |

pixel pitch | 2mm | |

| pixel structure | 1R1G1B | ||

| pixel density | 25 0000/m 2 | ||

| Module resolution | 160 (W)* 80 (H) | ||

| Module size | 320mm * 160mm _ | ||

|

OPTIC PARAMETER |

Single point luminance, chromaticity correction | have | |

| white balance brightness | ≥700 cd/㎡ | ||

| color temperature | 3200K—9300K adjustable | ||

| Horizontal viewing angle | ≥ 140° | ||

| vertical viewing angle | ≥ 120° | ||

| Visible distance | ≥3 meters | ||

| Brightness uniformity | ≥97% | ||

| Contrast | ≥3000:1 | ||

|

PROCCESSING PERFORMANCE |

Signal processing bits | 16 bits*3 | |

| grayscale | 65536 | ||

| control distance | Network cable: 100 meters, Optical fiber: 10 kilometers | ||

| drive mode | High gray-scale constant current source driver IC | ||

| frame rate | ≥ 60HZ | ||

| refresh rate | ≥ 1920 Hz | ||

| way to control | Synchronize | ||

| Brightness adjustment range | 0 to 100 stepless adjustment | ||

|

Make use ginseng number |

Continuous working time | ≥72 hours | |

| Typical life | 50,000 hours | ||

| Protection class | IP20 | ||

| range of working temperature | -20℃ to 50℃ | ||

| Operating humidity range | 10 %- 80% RH non-condensing | ||

| Storage temperature range | -20 ℃ to 60 ℃ | ||

|

Electricity gas ginseng number |

Operating Voltage | DC 4.2-5V | |

| Power Requirements | AC: 220×(1±10%)V, 50×(1±5%)Hz | ||

| Maximum power consumption | 650W/ ㎡ | ||

| Average power consumption | 260W/ ㎡ | ||

How much do you know about LED soft modules?

What is LED soft module? Compared with the conventional LED display, the soft-screen optoelectronic LED soft module is made of the hard-board PCB board and the hard-shell mask used in the conventional LED display, and has no flexibility. When encountering the need for radian and bending, it needs to be made with special processes such as chamfering, but the cost of using special processes will increase a lot, and the craftsmanship is not very beautiful.

LED module is a lighting decoration product composed of LED light-emitting diodes placed together according to certain rules and then packaged, plus some waterproof treatment and control systems. LED modules are widely used in LED products, and there are also great differences in structure and electronics. The simple is to use a circuit board and shell with LEDs to become an LED module, and to add some control to the complex, constant current source and related heat dissipation treatment make the LED life and luminous intensity better.

The connection surface of the LED soft module special-shaped screen is different from the traditional display screen. The traditional PCB board is made of glass fiber material, while the flexible module is equipped with high-strength locking and linking equipment, and the flexible FPC circuit made of flexible insulating substrate is selected. The board, mask and bottom shell are all made of rubber, which has high-strength anti-compression and anti-distortion capabilities, and can perfectly deal with various difficult problems of "playing on the topic, corners and corners".

The research and development of soft screen optoelectronic LED soft module is to solve the above problems conveniently. LED soft module is also called LED flexible screen, LED soft screen, its module has flexibility and can be folded and bent. The display principle of the LED soft module and the conventional LED display is the same, the difference is that the module of the flexible screen has softness and can be displayed and folded.