Flexible LED Module Soft LED Display Curved LED Display

When will small-pitch LED displays become popular?

When it comes to today's LED displays, small-pitch LED display technology is undoubtedly the focus of attention. Different from the traditional LED display that focuses on outdoor applications, the rapidly emerging small-pitch LEDs have focused their attention on the indoor application market that LEDs have never set foot in, and have launched a direct confrontation with the strong LCD splicing and DLP splicing. In the current field of indoor large-screen display, LCD splicing is a well-deserved NO.1. With the advantages of thinness and cost economy, it is widely used in many types of places, dominates the low-end market market, and actively penetrates into the high-end application market. However, for a long time, LCD splicing has an obvious shortcoming - the problem of stitching. Although the stitching is rapidly shrinking with the rapid maturity of liquid crystal display technology (the current minimum is 3.5mm), it is still one of the most important problems in the current display technology. , the one with the largest patchwork. This is in stark contrast to the small-pitch LED display with completely seamless display, and it is also an important reason why traditional LED display manufacturers are optimistic about small-pitch entry.

When it comes to today's LED displays, small-pitch LED display technology is undoubtedly the focus of attention. Different from the traditional LED display that focuses on outdoor applications, the rapidly emerging small-pitch LEDs have focused their attention on the indoor application market that LEDs have never set foot in, and have launched a direct confrontation with the strong LCD splicing and DLP splicing. In the current field of indoor large-screen display, LCD splicing is a well-deserved NO.1. With the advantages of thinness and cost economy, it is widely used in many types of places, dominates the low-end market market, and actively penetrates into the high-end application market. However, for a long time, LCD splicing has an obvious shortcoming - the problem of stitching. Although the stitching is rapidly shrinking with the rapid maturity of liquid crystal display technology (the current minimum is 3.5mm), it is still one of the most important problems in the current display technology. , the one with the largest patchwork. This is in stark contrast to the small-pitch LED display with completely seamless display, and it is also an important reason why traditional LED display manufacturers are optimistic about small-pitch entry.

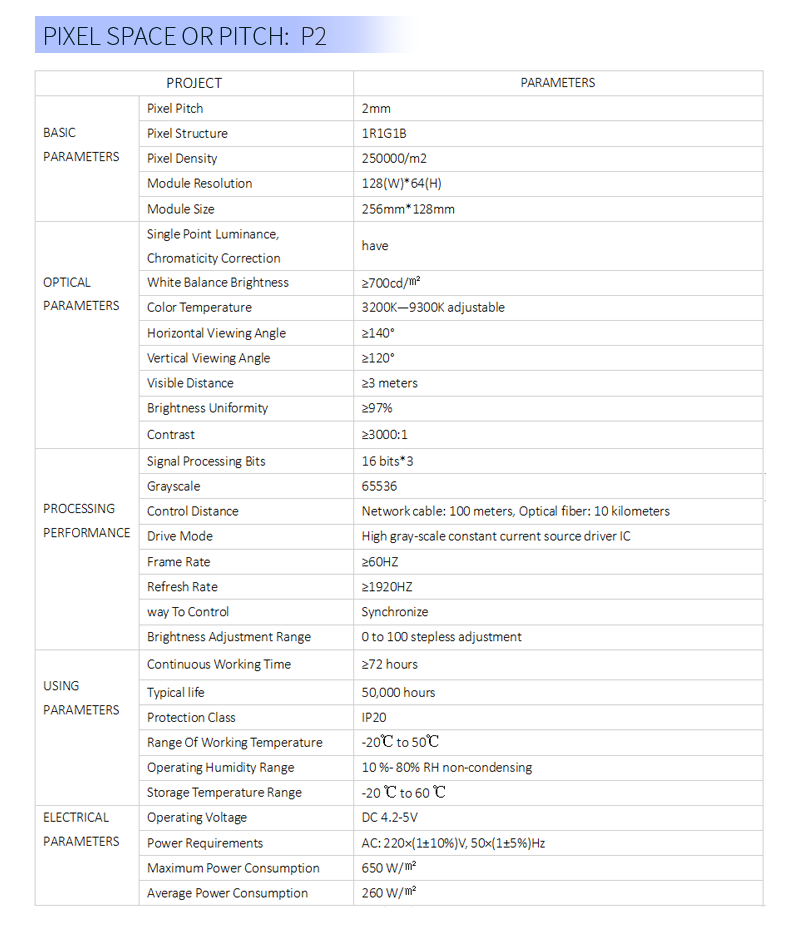

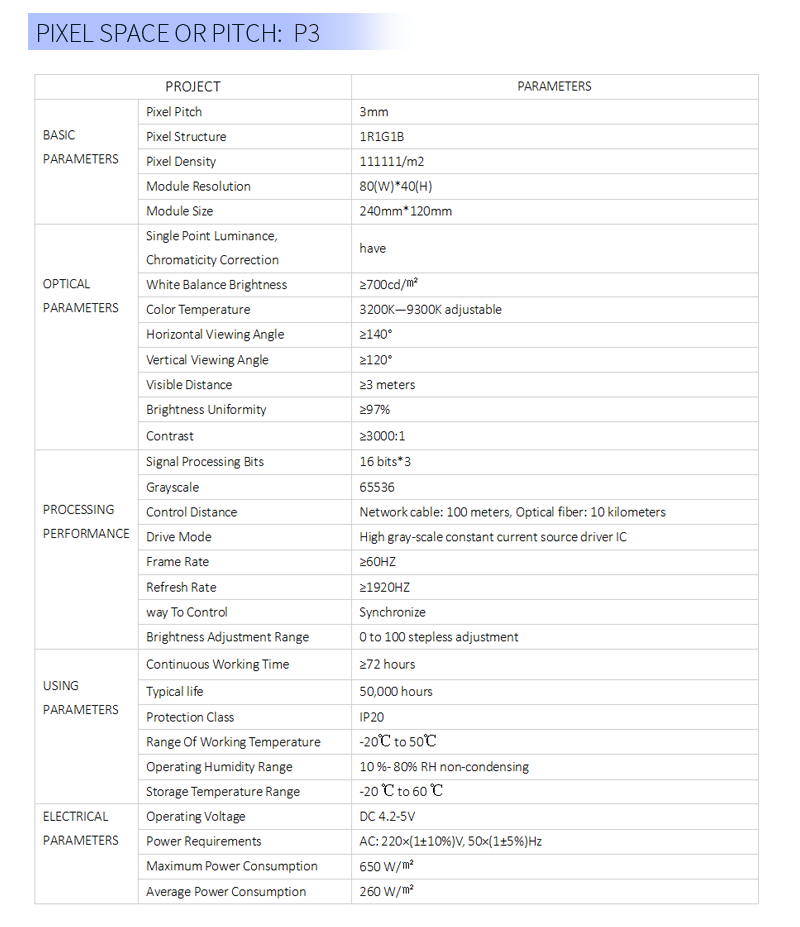

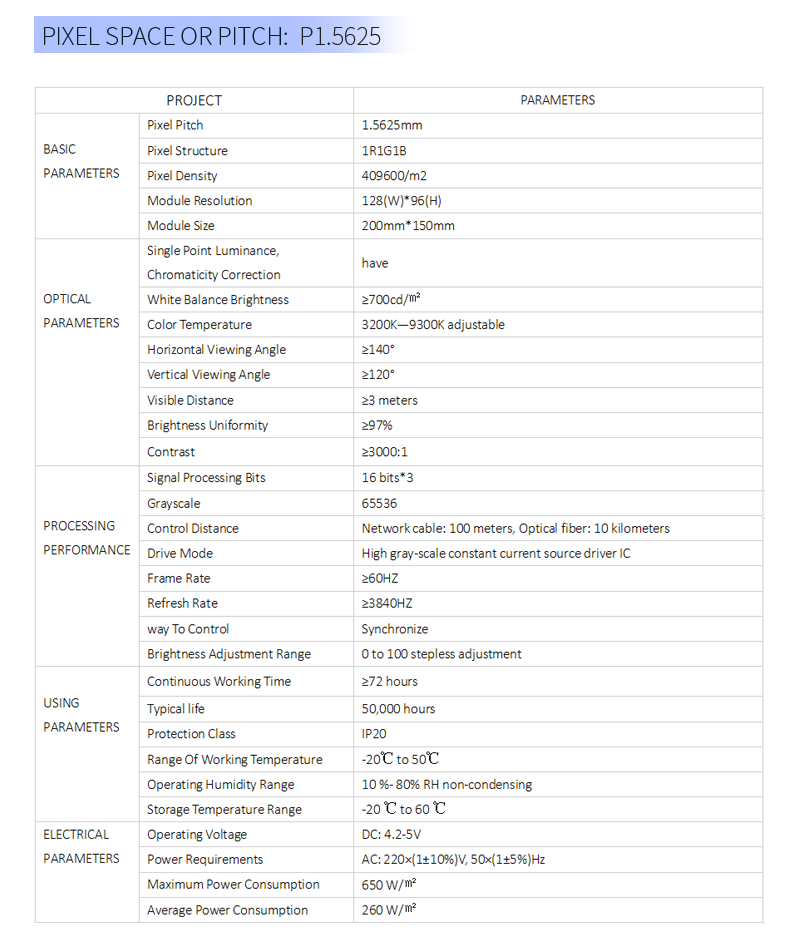

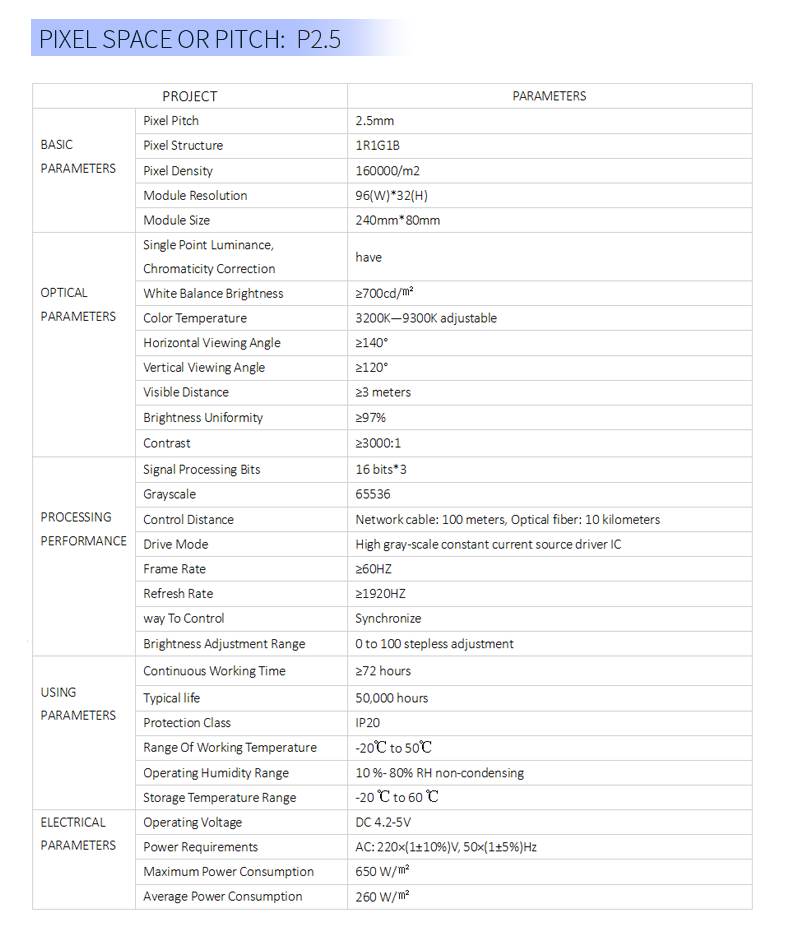

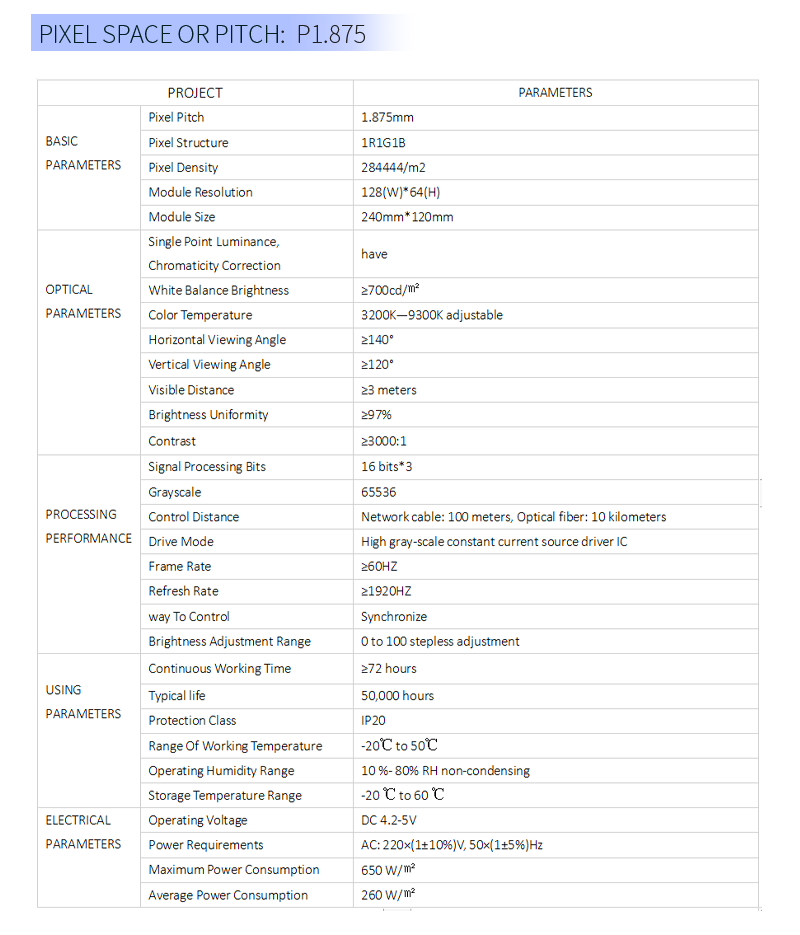

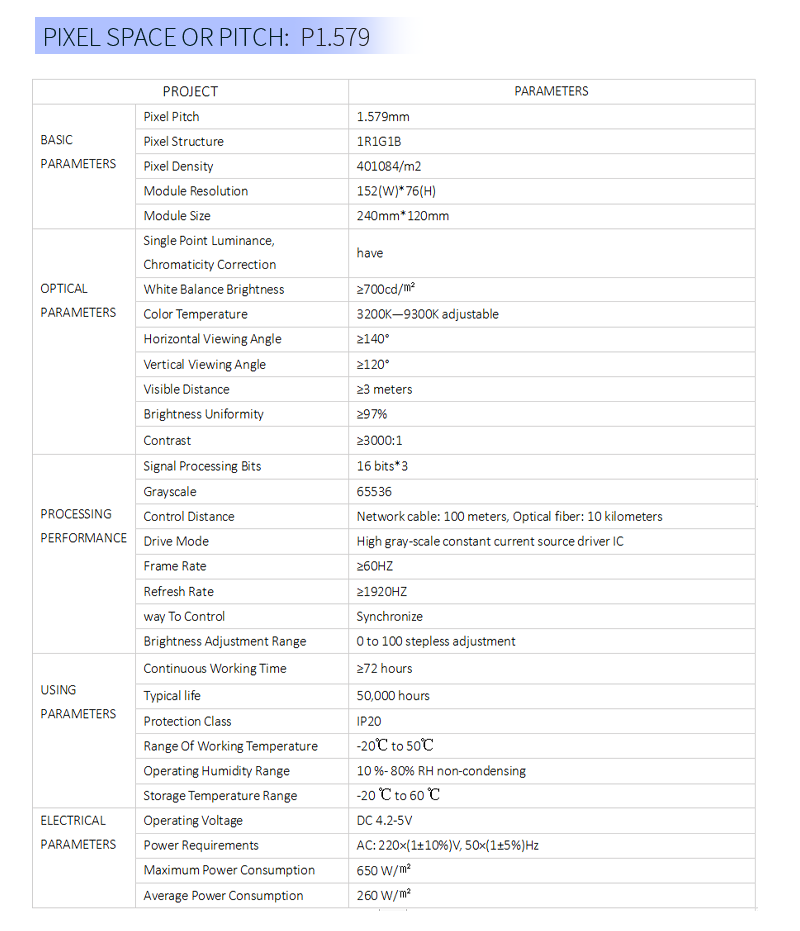

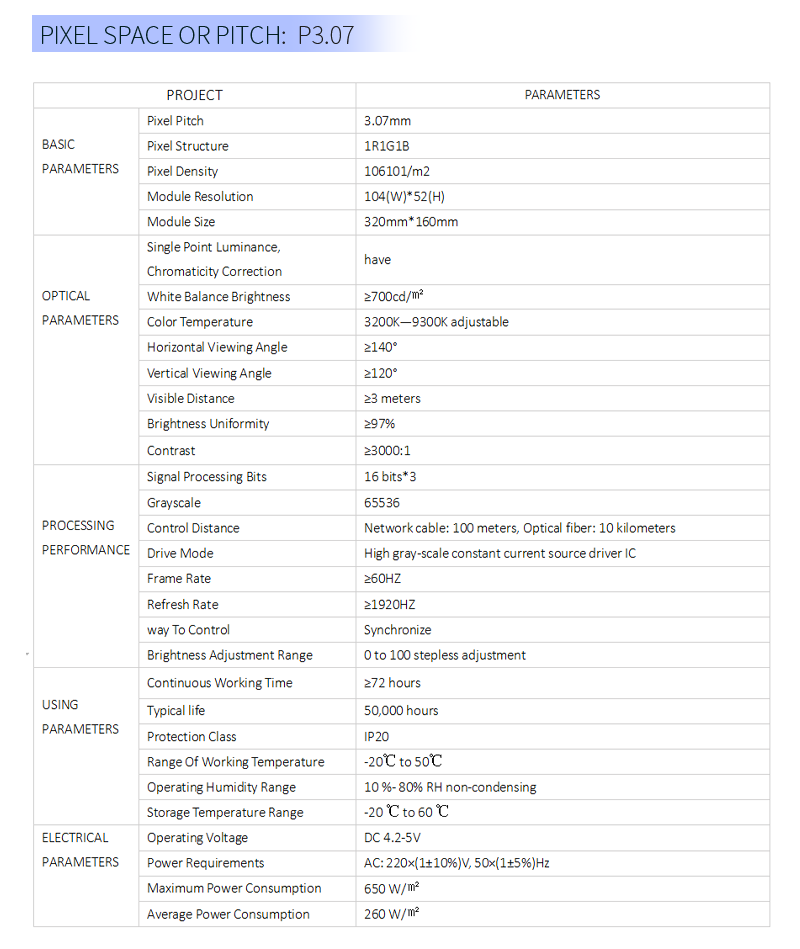

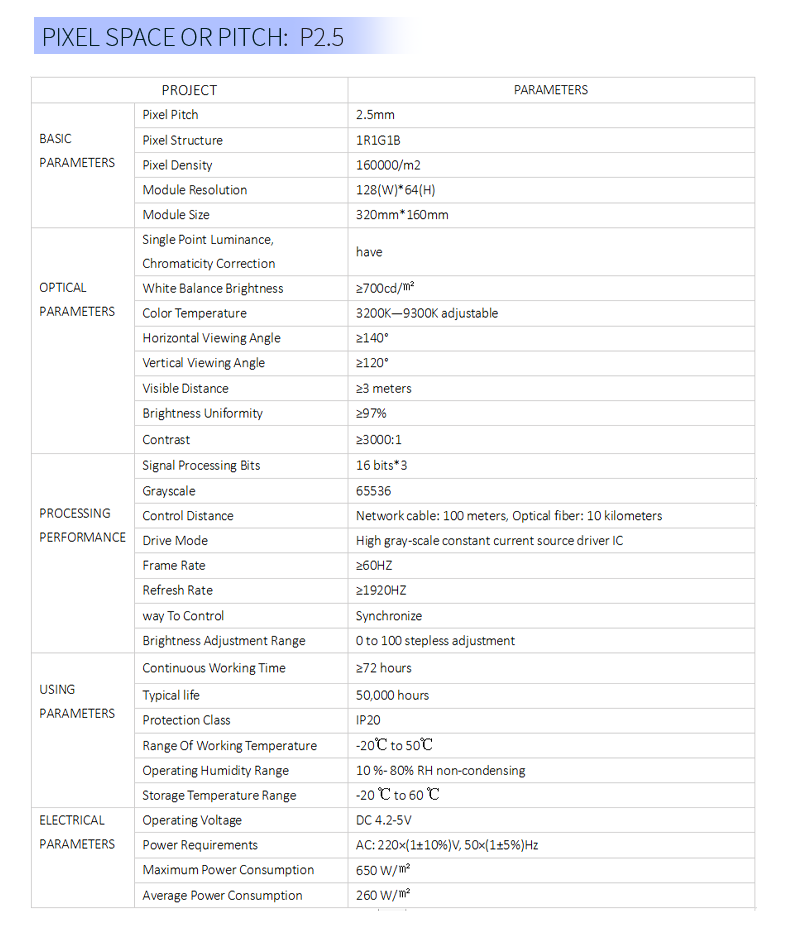

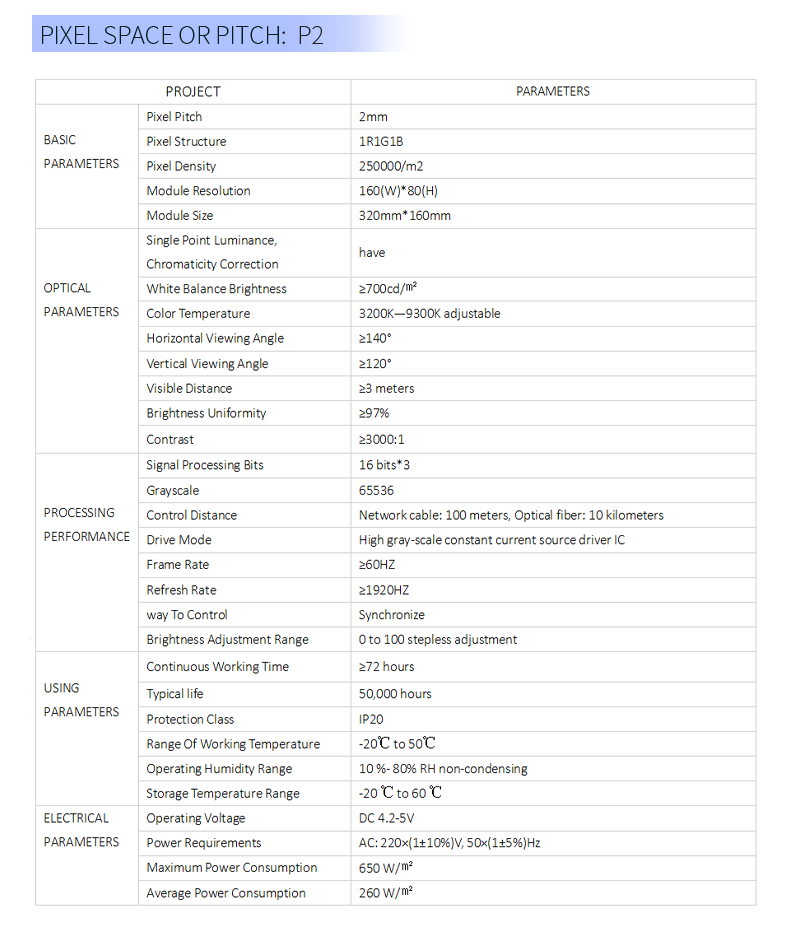

|

project |

parameter |

Remark |

|

|

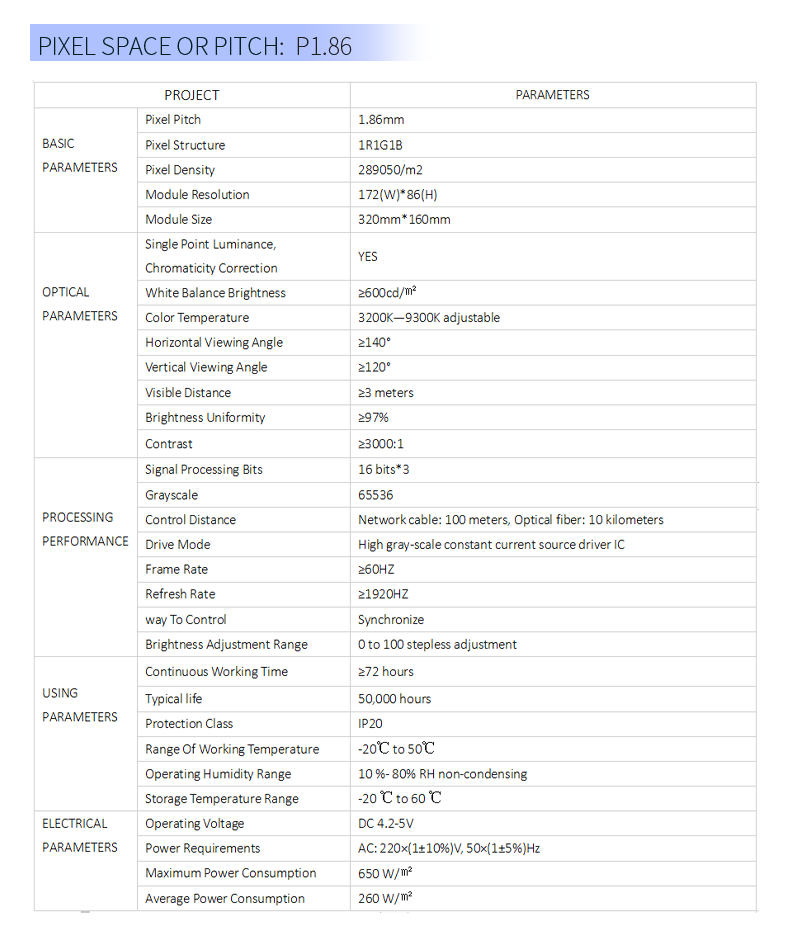

BASIC PARAMETER |

pixel pitch | 1.86mm _ | |

| pixel structure | 1R1G1B | ||

| pixel density | 289050 /m 2 | ||

| Module resolution | 172 (W)* 86 (H) | ||

| Module size | 32 0mm* 16 0mm | ||

|

OPTIC PARAMETER |

Single point luminance, chromaticity correction | have | |

| white balance brightness | ≥ 600 cd /㎡ | ||

| color temperature | 3200K—9300K adjustable | ||

| Horizontal viewing angle | ≥ 140° | ||

| vertical viewing angle | ≥ 120° | ||

| Visible distance | ≥3 meters | ||

| Brightness uniformity | ≥97% | ||

| Contrast | ≥3000:1 | ||

|

PROCCESSING PERFORMANCE |

Signal processing bits | 16 bits*3 | |

| grayscale | 65536 | ||

| control distance | Network cable: 100 meters, Optical fiber: 10 kilometers | ||

| drive mode | High gray-scale constant current source driver IC | ||

| frame rate | ≥ 60HZ | ||

| refresh rate | ≥ 1920 Hz | ||

| way to control | Synchronize | ||

| Brightness adjustment range | 0 to 100 stepless adjustment | ||

|

OPERATION PERFORMANCE |

Continuous working time | ≥72 hours | |

| Typical life | 50,000 hours | ||

| Protection class | IP20 | ||

| range of working temperature | -20℃ to 50℃ | ||

| Operating humidity range | 10 %- 80% RH non-condensing | ||

| Storage temperature range | -20 ℃ to 60 ℃ | ||

|

ELECTRIC PARAMETER |

Operating Voltage | DC 4.2-5V | |

| Power Requirements | AC: 220×(1±10%)V, 50×(1±5%)Hz | ||

| Maximum power consumption | 650W/ ㎡ | ||

| Average power consumption | 260W/ ㎡ | ||