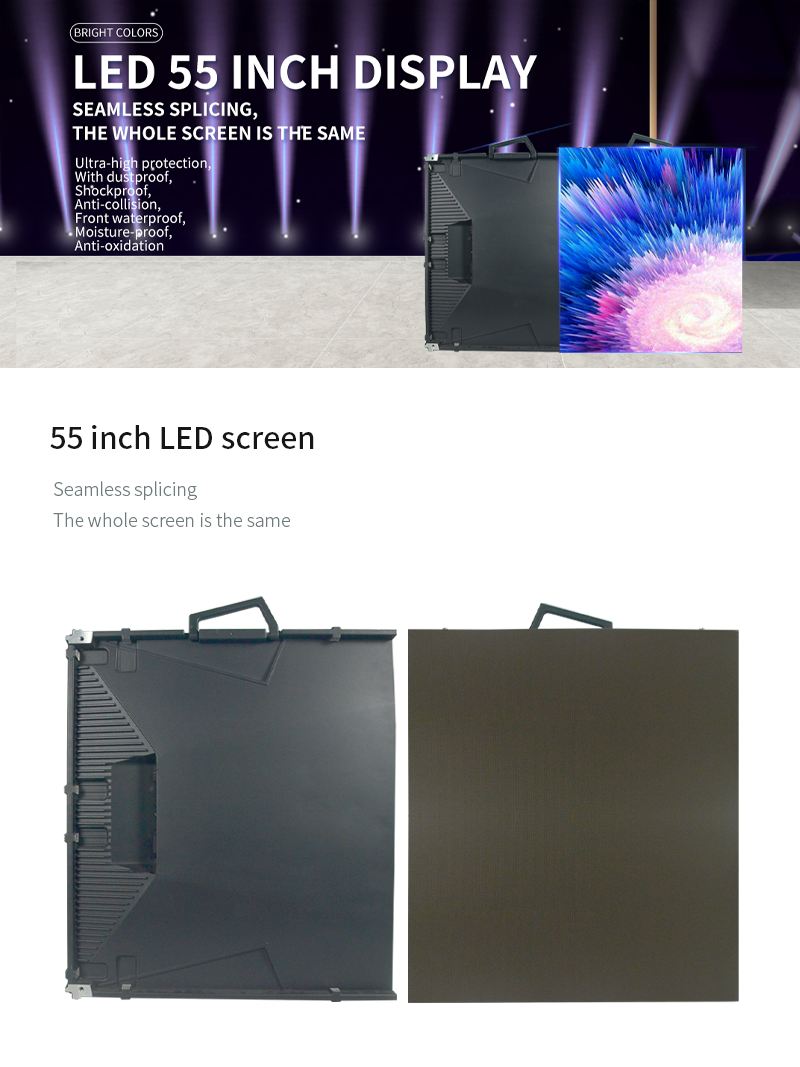

55 inch screen panel lcd indoor advertising display

What is the dynamic scanning of indoor high-definition led display?

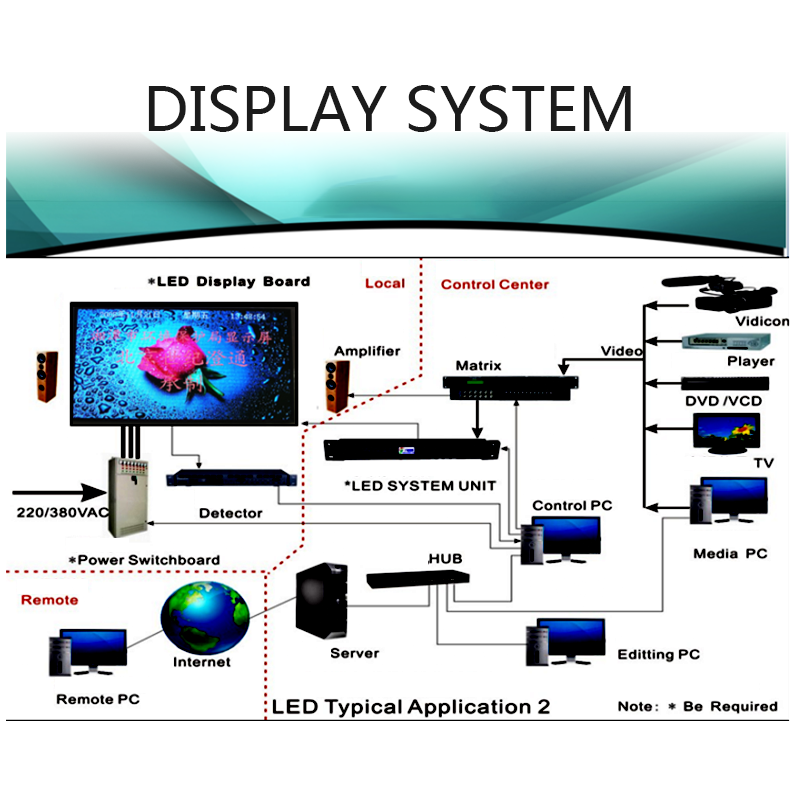

With the development of LED technology, the brightness of indoor high-definition LED displays is also increasing, and the size is getting smaller and smaller, which indicates that more indoor high-definition LED displays will become the general trend. However, due to the improvement of LED brightness and pixel density, new and higher requirements are brought to the control and driving of LED screens. As far as the general indoor screen is concerned, the current common control method adopts the row-column sub-control mode, which is commonly referred to as the scanning mode. At present, the driving modes of indoor high-definition led display screens include static scanning and dynamic scanning. Divided into static real pixels and static virtual, dynamic scanning is also divided into dynamic real image and dynamic virtual;

In the indoor high-definition led display, the ratio of the number of lines lit at the same time to the number of lines in the entire area is called scanning mode. The scan is also divided into 1/2 scan, 1/4 scan, 1/8 scan, 1/16 scan and other driving methods. That is to say, the drive mode of the display screen is different, so the settings of the receiving card are also different. If the receiving card was originally used on a 1/4 scan screen and is now used on a static screen, then the display on the display will be lit every 4 lines. Generally, the receiving card can be set. After connecting the sending card, display screen, computer and other main components, you can enter the relevant software on the computer to set. So here we will first introduce the scanning mode and principle of indoor high-definition led display.

1. Scanning method of indoor high-definition led display:

1. Dynamic scanning: Dynamic scanning implements "point-to-column" control from the output of the driver IC to the pixel points. Dynamic scanning requires a control circuit, and the cost is lower than that of static scanning, but the display effect is poor and the brightness loss is large. .

2. Static scanning: Static scanning is to implement "point-to-point" control from the output of the driver IC to the pixels. Static scanning does not require control circuits, and the cost is higher than dynamic scanning, but the display effect is good, stability is good, and brightness is lost. The advantages of being smaller, etc.

Second, the working principle of indoor high-definition led display 1/4 scan mode:

It is the time for each line of power supply V1-V4 to turn on 1/4 of the time according to the control requirements in one frame of image. The advantage of this is that the display characteristics of LEDs can be more effectively utilized and the hardware cost can be reduced. The disadvantage is that in 1 frame of image, each row of LEDs can only display 1/4 of the time.

Third, according to the indoor high-definition led display type scanning method classification:

1. Scanning method of indoor high-definition led display electronic display: P4, P5 are constant current 1/16, P6, P7.62 are constant current 1/8.

2. Scanning mode of outdoor and indoor high-definition led display electronic display: P10, P12 are constant current 1/2, 1/4, P16, P20, P25 are static.

3. The scanning methods of single and double color indoor high-definition LED display are mainly constant current 1/4, constant current 1/8 scan, and constant current 1/16 scan.

|

project |

parameter |

Remark |

|

|

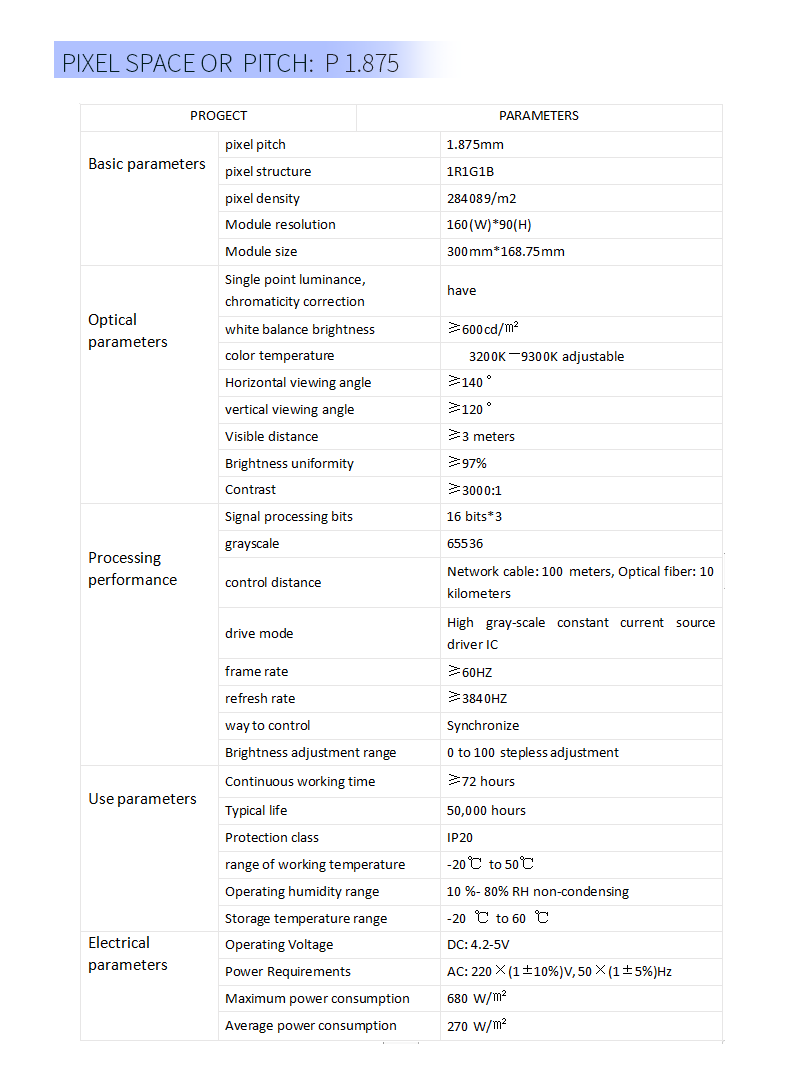

BASIC PARAMETER |

pixel pitch | 1.875mm _ | |

| pixel structure | 1R1G1B | ||

| pixel density | 284089 /m 2 | ||

| Module resolution | 160 (W)* 90 (H) | ||

| Module size | 300mm * 168.75mm | ||

| Box size | 1200*675mm | ||

| Box weight(Kg) | 19.5kg | ||

|

OPTIC PARAMETER |

Single point luminance, chromaticity correction | have | |

| white balance brightness | ≥600 cd/㎡ | ||

| color temperature | 3200K—9300K adjustable | ||

| Horizontal viewing angle | ≥ 160° | ||

| vertical viewing angle | ≥ 160° | ||

| Visible distance | ≥3 meters | ||

| Brightness uniformity | ≥97% | ||

| Contrast | ≥3000:1 | ||

|

PROCCESSING PARAMETER |

Signal processing bits | 16 bits*3 | |

| grayscale | 65536 | ||

| control distance | Network cable: 100 meters, Optical fiber: 10 kilometers | ||

| drive mode | High gray-scale constant current source driver IC | ||

| frame rate | ≥ 60HZ | ||

| refresh rate | ≥ 384 0 Hz | ||

| way to control | Synchronize | ||

| Brightness adjustment range | 0 to 100 stepless adjustment | ||

|

Operation parameter |

Continuous working time | ≥72 hours | |

| Typical life | 50,000 hours | ||

| Protection class | IP20 | ||

| range of working temperature | -20℃ to 50℃ | ||

| Operating humidity range | 10 %- 80% RH non-condensing | ||

| Storage temperature range | -20 ℃ to 60 ℃ | ||

|

Electric parameter |

Operating Voltage | DC: 4.2-5V | |

| Power Requirements | AC: 220×(1±10%)V, 50×(1±5%)Hz | ||

| Maximum power consumption | 680W / ㎡ _ | ||

| Average power consumption | 270W / ㎡ _ | ||